Metallography application

Pictorial Image Processor supports a specialized task of calculation of ASTM grain size number in two-phase metallographic images. The ASTM grain size number calculations are performed according to 2 standards, ASTM E112-96 and Australian AS173-1976. The difference between the standards is minor, the US standard employs formulae to perform the calculations while the Australian standard employs a look up table. The definitions of can be found in the appropriate standards. Some information can also be found on other metallography sites for example metallography.com.

This feature of Pictorial Image Processor diverges from the general philosophy of the application where all operations are available in the project window. The justification for this diversion is specificity of the task and limited scope of application.

The special operation of grain size number calculation is applicable only to spatially calibrated binary images. In full image size view for binary image only there is menu "Special" which provides access to the ASTM grain size menu if the project is spatially calibrated. Spatial calibration can be performed via "Attributes" menu in the main window.

During the calculations the grains size measurement algorithm assumes that the image consists of the set of foreground areas (grains) separated by the background lines (grain boundaries) at least 1 pixel thick. Images of this type are usually obtained by watershed or skeletonisation operations and partition the image into the adjacent blobs (grains).

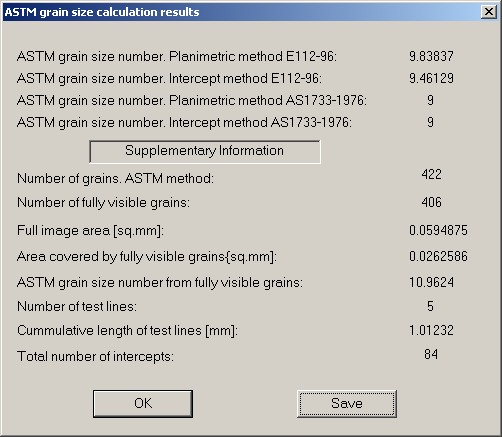

During the calculation of the grain size two methods, described in ASTM standard E112-96 are used: planimetric and intercept. In the planimetric method the number of areas is countered according to the guidelines of the standard and the grain size number is calculated based on the average area of the grain blob. In the intercept method a number of random lines across the image is generated and the grain size number is calculated based on the average length of line segments between two grain boundaries. The results of the calculations are presented in the following form

The results can be saved in a comma delimited CSV file.